3D PRINT FASTER

No products in the cart.

$12,995.00 – $16,495.00

The EVO 2X is our largest commercial 3D printer, enabling professionals to create high-quality, large-scale prints. It offers advanced features and a wide range of compatible materials for various applications. Download the specification sheet.

With its 5,544-cubic-inch build volume, the EVO 2X has a build height of 22 inches and a 24 x 12 inch wide print bed. The EVO 2X platform offers nearly twice the width as Airwolf 3D’s EVO-22 machine. For best results with ABS and similar materials, a 22 x 11 build footprint is recommended.

The EVO 2X is our largest commercial 3D printer designed for professional use. With its massive build volume and advanced technology, it enables users to create large-scale, high-quality 3D prints with ease. Its precision and accuracy guarantee exceptional results for architectural models, prototypes, and production parts. The EVO 2X is equipped with user-friendly features such as a touchscreen interface, remote monitoring, and easy filament loading. It also offers a wide range of compatible materials, enabling users to explore various applications. Whether you need to print intricate designs or large-scale objects, the EVO 2X is the ultimate solution for businesses seeking to scale up their additive manufacturing capabilities.

Manufacture real-scale, end-use parts in over 40 different materials. Optimized for large-part production, the 24 x 12 x 22 inch enclosed build volume is ideal for producing large parts. Compatible materials include ABS, HydroFill Water-Soluble Support, polycarbonate, and more. When printing ABS and similar materials, a 22 x 11 inch build footprint is recommended.

Manufacturing large parts has never been easier, thanks to proprietary Tri-Heat™ technology. Two internal chamber heaters capable of heating the chamber to at least 70C and a high-temperature heat bed capable of 160C create the optimal thermal environment for the formation of strong, smooth parts.

Enjoy Airwolf 3D’s proprietary auto-leveling technology along with AutoPrime, and Sweep. Ultra-durable Extended-Life nozzles save time and money while providing higher precision, speed and efficiency.

Breathe easy. An oversized air filtration system compliments this large 3d printer and works to actively contain UFP and VOC emissions during the desktop manufacturing process.

Gone are the days of losing hours of production time due to power failure, an accidentally unplugged machine, or other interruptions. Just turn your machine back on, and resume production where you left off.

Print with peace of mind. Ensure that your print will continue, even if you run out of material or need to purge a clogged hot end. Simply place the print head where you left off and FailSafe™ will do the rest.

Plug the EVO2X printer into a standard wall outlet, just like any other appliance.

Fill out our form to receive a free Airwolf 3D sample part. Part is printed with ABS thermoplastic. Sample part program is limited to US addresses only.

Request SampleBoth the brain and heart of the EVO Additive Manufacturing Center, Airwolf 3D’s proprietary GENESIS Microcontroller drives the leaps and bounds that EVO has made in desktop additive manufacturing technology.

Fully proprietary and engineered from the ground up to support high-performance industrial manufacturing, the GENESIS board is an automotive-grade 32-bit redundant embedded controller that delivers 2-3 times higher speeds, more precision, and greater control at ultra-high temperatures than any other desktop 3D manufacturing system on the market.

Control EVO 2X with a single touch. A spacious 7″ full-color touch display makes it easy to control everything from PartSave™, material selection, internal ambient temperature, and expert settings to an on-screen keyboard for writing and executing g-Code on the fly.

The CoreXY Motion System receives a leading-edge update thanks to CNC-style linear precision guides. Up until now, the successful integration of a heavy-duty linear-guide-based motion control system was available only in high-end systems at over five times the price of the EVO 2X. One of the most future-proof design elements of the EVO AMC, the linear-guide-based CoreXY Motion System provides unparalleled manufacturing precision with zero maintenance.

This white paper reviews the technical requirements for large format additive manufacturing of parts in acrylonitrile butadiene styrene (ABS) material with fused deposition modeling equipment. Read the white paper to learn:

- Heat requirement

- Power requirements

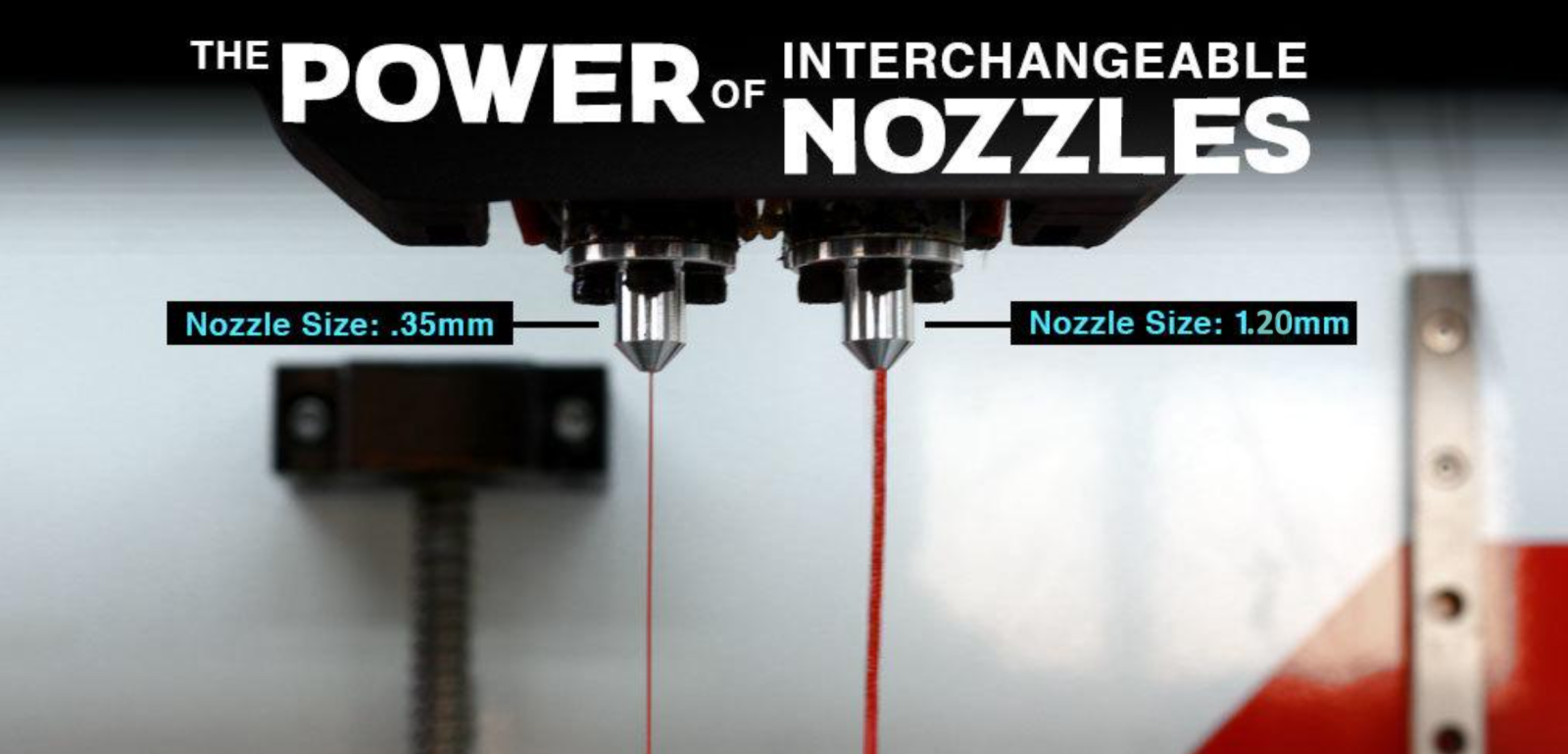

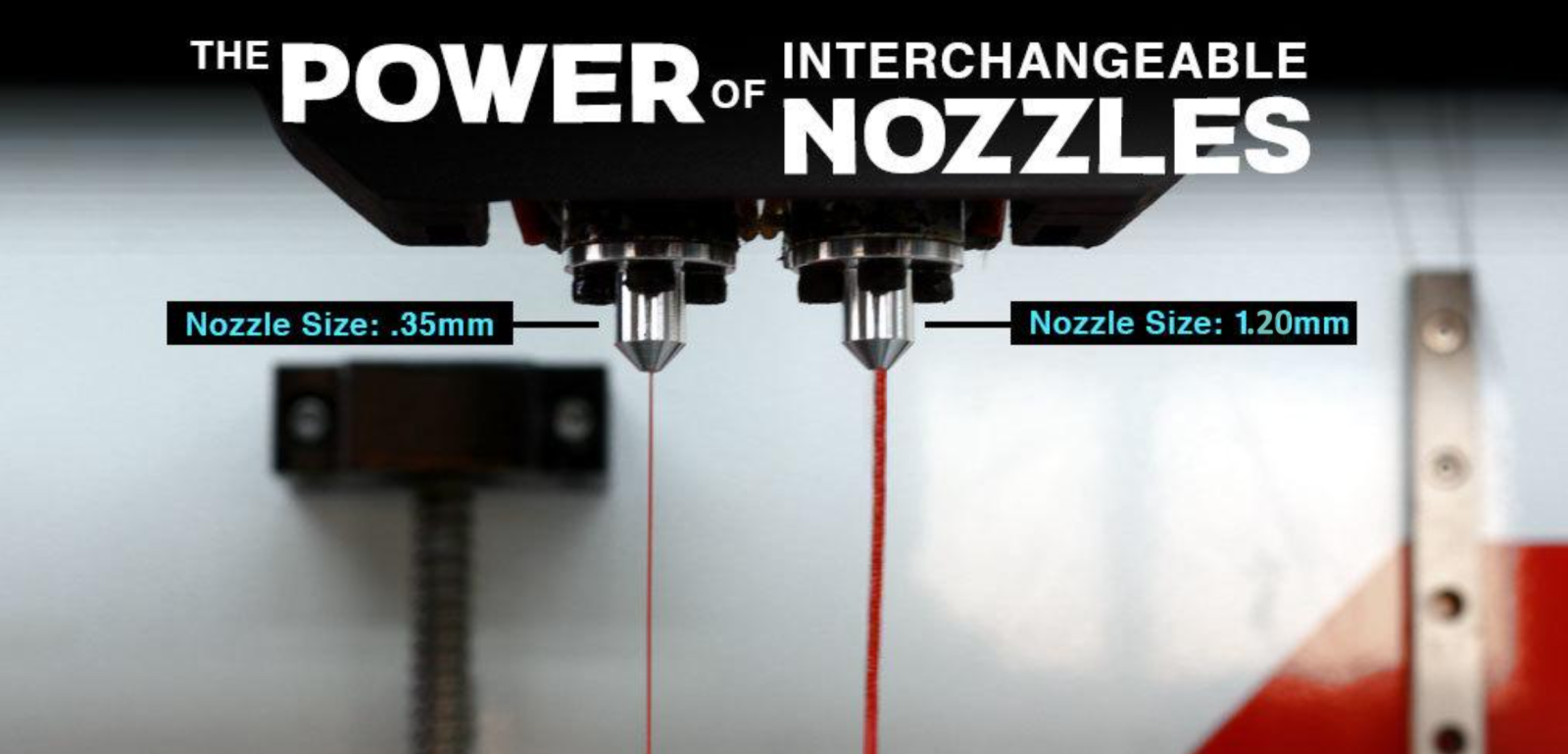

- The math behind nozzle size

Manufacture large parts quickly with the EVO 2X’s industry-leading material deposition rate. A cartridge-style planetary extruder assembly achieves increased torque capacity for faster extrusion speeds while an unbreakable three-bolt-reinforced hot end precisely distributes over 40 materials ranging from PLA and ABS to exotic materials including carbon-fiber-reinforced nylon and PC as well as HydroFill, Airwolf 3D’s proprietary water-soluble support.

Performance is further optimized by extended-life replaceable nozzles that help minimize part distortion.

The EVO 2X’s bulletproof z stage comprises a proprietary coupling linking a ball screw with a stepper motor and is powerful enough to support up to 50 pounds and provides precision of nearly one thousandth of an inch over its 22-inch build height, providing incredible accuracy.

Approximately the size of a human hair, the precision movement is barely discernible by the human eye.

The strongest machine on the market, the EVO 2X has a 100% aluminum unitized frame constructed in a rigid monocoque to maximize structural integrity while minimizing bulk and weight. The metal frame and unitized build platform supports up to 50 pounds and also employs one-piece construction to save weight and space in order to maximize strength while minimizing part distortion.

The EVO 2X has power in reserves, easily adapting to ultra-demanding applications in even the harshest environments. An automatic circuit breaker provides a safer, more reliable, and more serviceable system than conventional fuse replacement.

Though rugged and unbreakable, the EVO 2X is light enough to transport easily.

Manufacture in over 40 materials ranging from PLA and ABS to exotic materials like metal, carbon fiber-reinforced nylon, polycarbonate, and HydroFill Water-Soluble Support. Produce larger, more complex parts than ever before, thanks to the carefully controlled thermal environment offered by EVO 2X’s Tri-Heat™ Enclosed Build Chamber and Integrated Filament Drying System.

With our free online training program (www.airwolf3du.com) you will learn how to unbox and operate your equipment to full proficiency.

As an add-on, Airwolf 3D offers an optional service to set up your printer, software and provide onsite training. Your equipment investment pays even greater dividends when it is put to skillful and safe use. Airwolf 3D technicians will arrive onsite for a custom training. Your operator will achieve higher levels of proficiency and realize the full potential of your spend. We are dedicated to providing our customers with quality training and part consulting services. With this package, our team will handle the installation process.

| Shipping Weight | 200 lbs |

|---|---|

| Shipping Dimensions | 40 × 40 × 36 in |

| Extruder Configuration | G-Series High-Torque Cartridge-Style Planetary Dual Extrusion System |

| Recommended Max. Print Speed* | 250 mm/sec |

| Build Volume | 24"' x 12" x 22", 610 mm x 305 mm x 560 mm |

| Travel Speed | 125+mm/sec MAX |

| Max. Extruder Temp. | 315°C |

| Max. Bed Temp. | 160°C |

| Minimum Layer Height | 40 microns |

| Recommended Layer Height | 180 microns or above |

| Calibration | Auto-Leveling |

| Materials | Metal, Over 40, incl. ABS, PC, PP, Nylons, TPE, TPU |

| Filament Size | 2.85mm +/-0.10 |

| Nozzle Size | 1.2 mm Heavy Duty included, 1.0 mm, 0.8 mm, 0.5 mm and 0.35 mm optional |

| Weight (lbs) | 170 lbs. |

| Height (in) | 36" |

| Width (in) | 40" |

| Depth (in) | 24.5" |

| Frame Construction | One-piece aluminum main frame, polycarbonate |

| Motion System | Core XY |

| Enclosed Print Chamber | Yes |

| Heated Chamber | Yes |

| Heated Bed | Yes |

| Print Plate Material | MaxGrip Composite Plate |

| Cooling Fans | Dual Part Cooling, Single 60 mm Extruder |

| Display | Touchscreen 7" |

| Provided Software | APEX |

| Connectivity | Ethernet, USB Cable, USB Drive, Wi-Fi |

| Print via Removable Device | USB Drive, USB Stick + Onboard Storage |

| Maintenance Tools Included | Allen Wrenches, Micro Drill Bit Set |

| Power Requirements | Input "100 – 240 V 4 A, 50 – 60 Hz", Output "221 W max. 24 V DC, 9.2 A" |

| Accessories Included | 0.80 Extended-Life Nozzle, Nozzle-Cleaning Tool, Wolfbite 2 oz., 2 Spools ABS, 1 USB Drive |

| Filament Included | Yes |

| Bed Adhesive | Wolfbite MEGA, Wolfbite NANO, Wolfbite NITRO, Wolfbite Original, Wolfbite ULTRA |

| Warranty | 12 Month, by Manufacturer |

| Email Support | tech@airwolf3d.com |

| Phone Support | +1 (949)478-2933 |

| Tutorials | http://airwolf3du.com/ |

| Upgradeable | Yes |

| Manufacturer Lead Time | 2 Weeks |

| Options | Add Onsite Training with Set Up / Installation, With Free Online Training |

Main Power: 15-amp dual-pole AC circuit breaker GENESIS Microcontroller: (2) 5-amp and (1) 25-amp fuses to cover mosfets, heaters, stepper motors, and logic Heated Bed: • 180C thermal fuse Hot End: • 25W low power consumption heaters • Polyamide insulators Power Supply: Short circuit/overload/over voltage/over temperature

Hot End: Automatic shut-off on overtemp/overcurrent Heat Bed: Automatic shut-off on overtemp/overcurrent Chamber Heater: Automatic shut-off on overtemp/overcurrent Stepper Motors: Automatic shut-off on overcurrent Fans: Automatic shut-off on overcurrent Lights: Automatic shut-off on overcurrent

Hot End: Automatic cool down after non-use Heated Bed: Automatic cool down after non-use Chamber Heater: Automatic cool down after non-use

| Printing Performance | |

| Extruder Configuration | G-Series High-Torque Cartridge-Style Planetary Dual Extrusion System |

|---|---|

| Build Volume | 24"' x 12" x 22", 610 mm x 305 mm x 560 mm |

| Recommended Max. Print Speed* | 250 mm/sec |

| Heated Chamber | Yes |

| Travel Speed | 125+mm/sec MAX |

| Max. Extruder Temp. | 315°C |

| Max. Bed Temp. | 160°C |

| Calibration | Auto-Leveling |

| Upgradeable | Yes |

| Filament Compatibility | |

| Materials | Metal, Over 40, incl. ABS, PC, PP, Nylons, TPE, TPU |

| Filament Size | 2.85mm +/-0.10 |

| Printer Design | |

| Weight (lbs) | 170 lbs. |

| Height (in) | 36" |

| Width (in) | 40" |

| Depth (in) | 24.5" |

| Frame Construction | One-piece aluminum main frame, polycarbonate |

| Heated Bed | Yes |

| Print Plate Material | MaxGrip Composite Plate |

| Connectivity & Accessories | |

| Provided Software | APEX |

| Connectivity | Ethernet, USB Cable, USB Drive, Wi-Fi |

| Print via Removable Device | USB Drive, USB Stick + Onboard Storage |

| Maintenance Tools Included | Allen Wrenches, Micro Drill Bit Set |

| Filament Included | Yes |

| Help & Support | |

| Warranty | 12 Month, by Manufacturer |

| Email Support | tech@airwolf3d.com |

| Phone Support | +1 (949)478-2933 |

| Tutorials | http://airwolf3du.com/ |

| Manufacturer Lead Time | 2 Weeks |